Project Overview

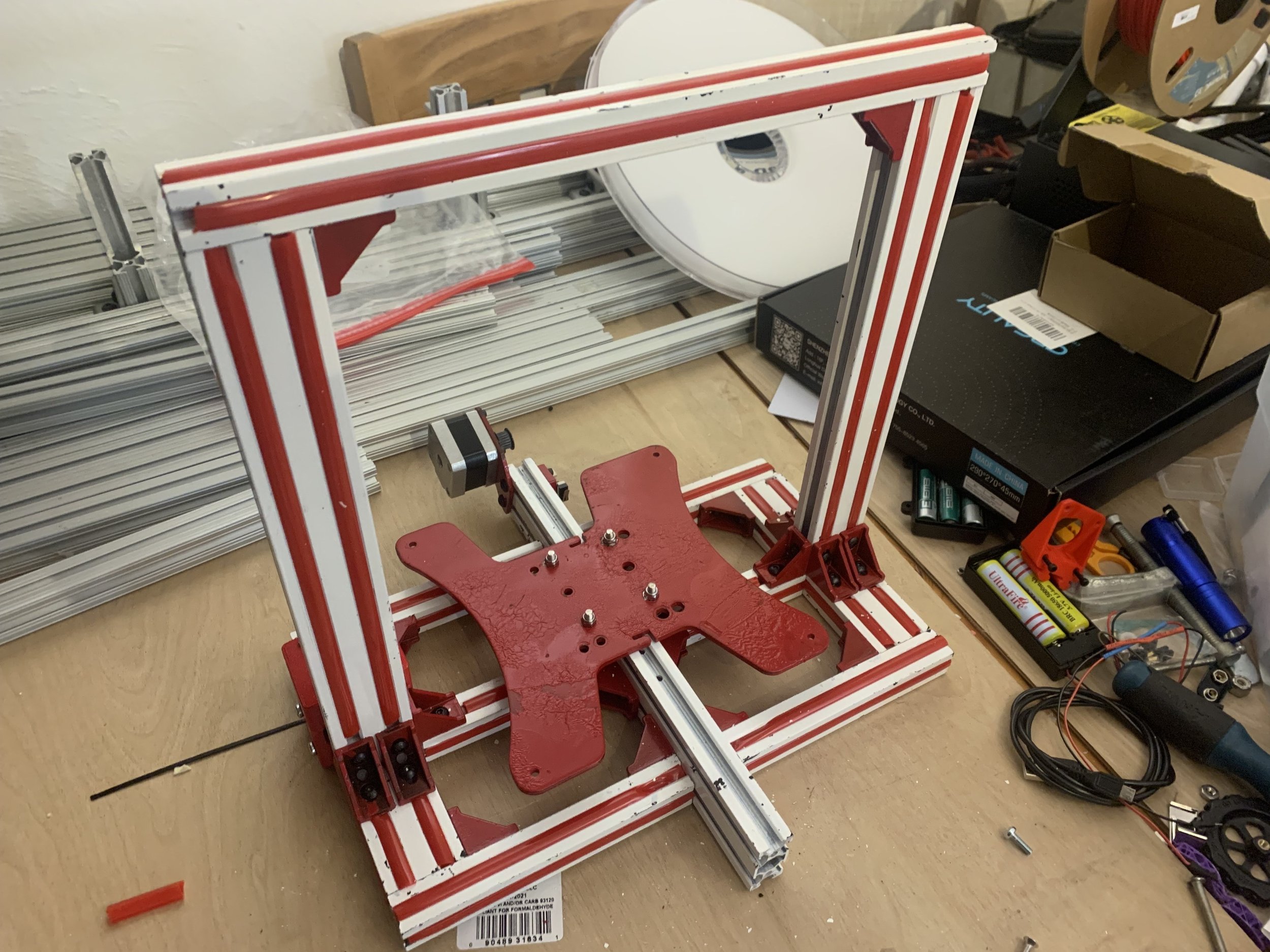

For my senior year project in high school, I decided to design, manufacture, and assemble a working Rep-Rap-style 3D printer from scratch, using as many parts as I had to understand the pros and cons of building a printer from scratch versus buying a kit.

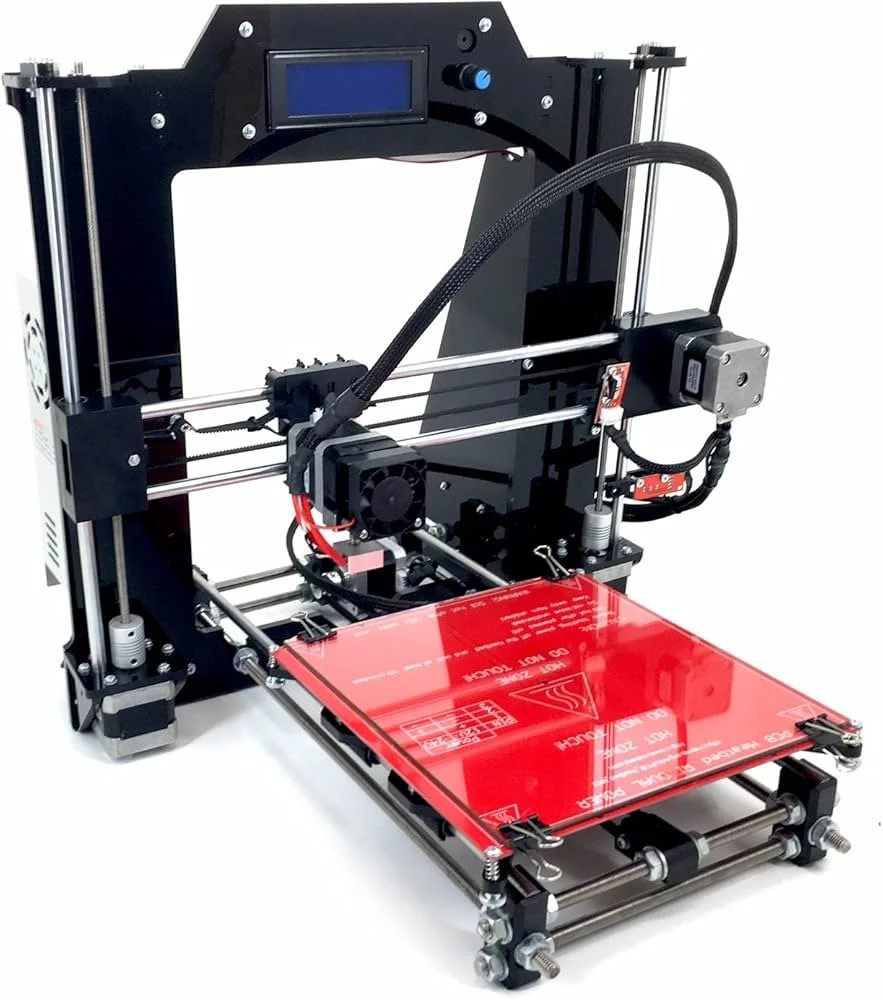

My printer design took heavy inspiration from RepRap-style printers. These 3D printers have cartesian-style frames, which allows the print bed to move linearly perpendicular to the moving print head.

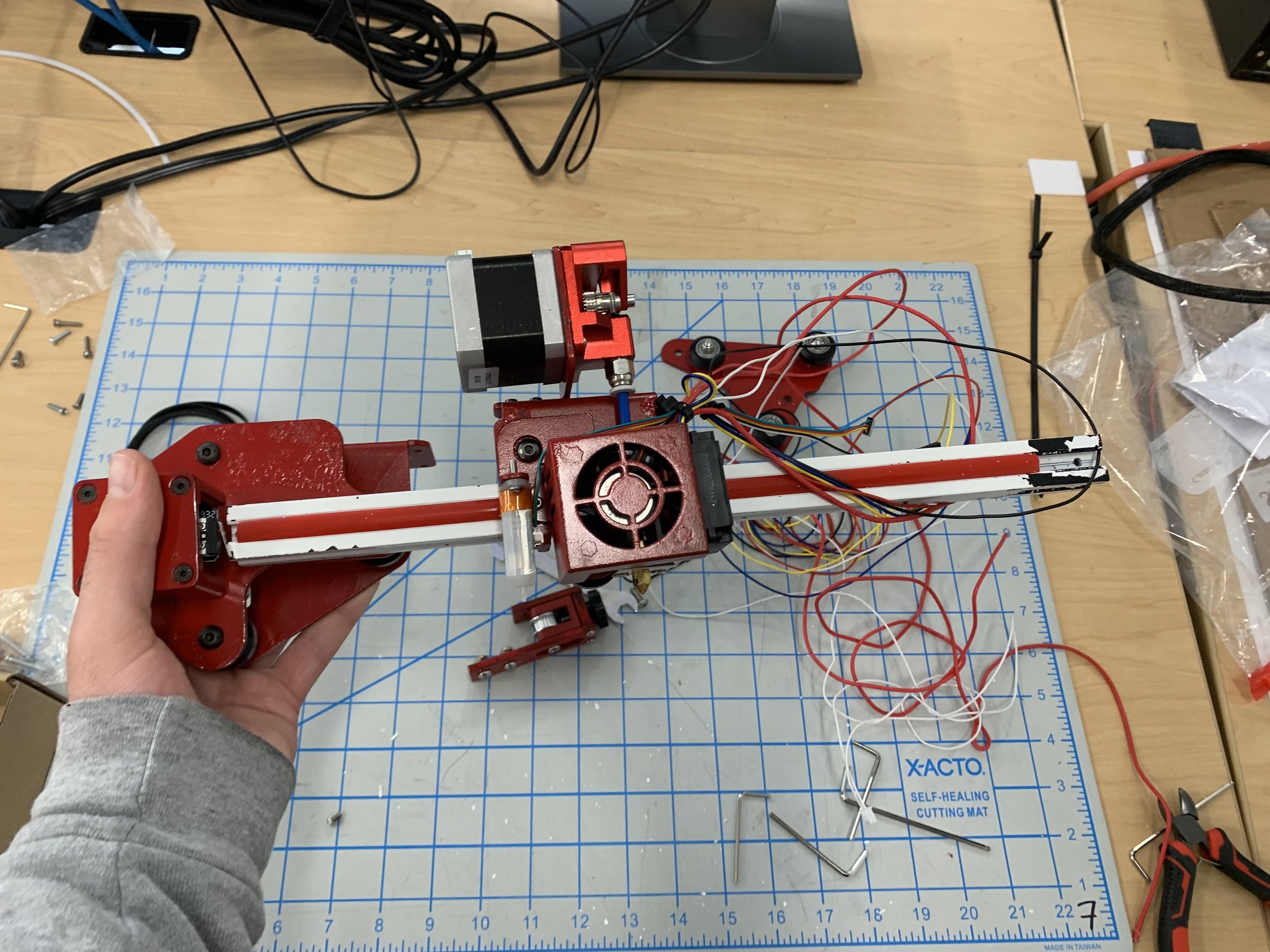

My printer has a custom frame which I designed through Computer-Aided Design and machined in my robotics team’s machine shop. It primarily uses 2020 and 2040 aluminum extrusions and L brackets to mount them perpendicular to each other. My printer runs a direct drive setup for its extruding motor because of its usability with flexible filaments and lower failure rates.

The software I used was Marlin because it is the primary software that the motherboard I had on hand used. Marlin is also easily configurable and flash-friendly making firmware modifications unchallenging.

Video of Final Product